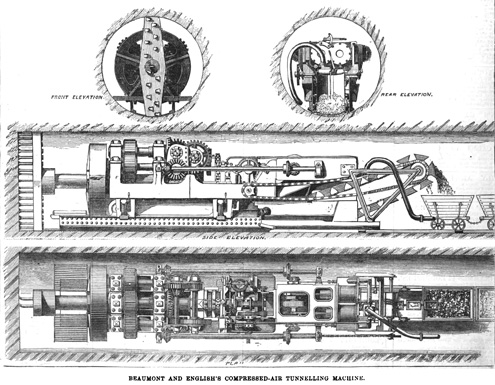

Beaumont-English Tunnel Boring Machine

A compressed air-driven tunnel boring machine built in 1880 for the first Channel Tunnel (abandoned before completion).

Compressed air, used to drive the machine, was supplied by a

steam-driven compressor at the mouth of the tunnel, and carried to the

boring machine by a flexible pipe. In operation, the boring machine

worked in alternating phases.

Compressed air, used to drive the machine, was supplied by a

steam-driven compressor at the mouth of the tunnel, and carried to the

boring machine by a flexible pipe. In operation, the boring machine

worked in alternating phases.

In the Cutting Phase, the cutting head rotated, the bucket chain was in motion, and the superstructure (the upper part of the machine carrying the cutting head, the motors, the transmission and the bucket chain) advanced slowly atop the base section which carried the weight of the superstructure and remained stationary, resting on the tunnel floor.

Spoil, which collected behind the cutting head, was shovelled into a scoop and channelled under the base section. As the superstructure moved forward, the buckets scooped up the spoil and dumped it in railway wagons behind the engine. The railway was extended - rails added by the operating crew - in step with the machine's forward progress.

The cutting head and the (lead screw) advancing mechanism were driven by separate compressed-air motors, working together during this phase.

When the superstructure reached the forward limit of its travel on the base section, the cutting head and bucket chain stopped, and the machine entered the Base Advancing Phase.

In this phase, boring was halted while the base section was moved forward along the tunnel floor. To enable it to move, jacks were lowered from the superstructure, placing its weight directly on the tunnel floor and lifting the base section clear of the ground. The second compressed-air motor was then run in reverse to slide the base section forward while the superstructure remained stationary. When the base section reached its forward limit of travel (close to the face of the tunnel), the jacks were raised until the base section again rested on the tunnel floor and the superstructure on the base section, and the cycle was repeated.

No drawings or descriptions (other than those published in “The Illustrated London News” (above) of this machine survive. Many details in the model are therefore based on guesswork and conjecture.